OUR BUSINESS

LIGHT STEEL BUILDING

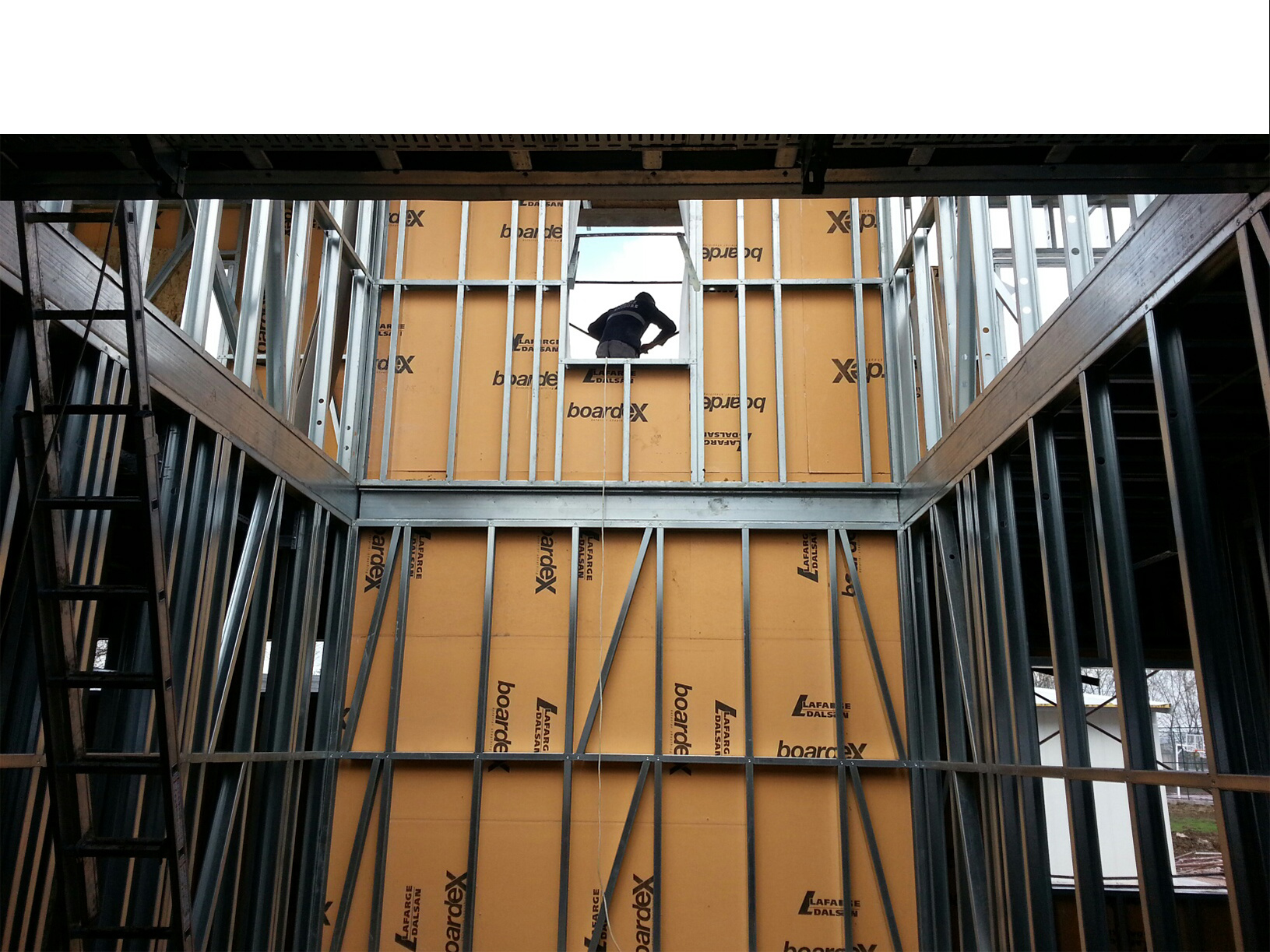

Light Gauge Steel (LGS) construction is a modern building method that utilizes cold-formed steel components to create strong, durable, and efficient structures. LGS is widely used in residential, commercial, and industrial projects due to its numerous advantages, including lightweight properties, high strength, and sustainability.

What is Light Gauge Steel?

Light Gauge Steel refers to thin sheets of galvanized steel that are cold-formed into structural components such as C-channels, U-channels, and Z-sections. Unlike hot-rolled steel, which is thicker and heavier, LGS is manufactured at room temperature through a precise roll-forming process, ensuring consistency and accuracy in dimensions.

ADVANTAGES OF LIGHT GAUGE STEEL

High Strength-to-Weight Ratio

Despite being lightweight, LGS offers exceptional strength and load-bearing capacity, making it suitable for a variety of structural applications.

Precision and Consistency

Since LGS components are manufactured using computer-controlled roll-forming machines, they maintain consistent quality and precise dimensions, reducing on-site errors and construction time.

Faster Construction

LGS structures are prefabricated off-site, which significantly speeds up the construction process. This results in reduced labor costs, shorter project timelines, and minimal material waste.

Durability and Longevity

Galvanized and coated steel components are highly resistant to corrosion, termites, and mold, ensuring a long lifespan with minimal maintenance requirements.

Fire and Seismic Resistance

Steel is non-combustible and performs well in fire-rated applications. Additionally, LGS structures can be engineered to withstand earthquakes due to their flexibility and lightweight nature.

Eco-Friendly and Sustainable

LGS is 100% recyclable and produces less construction waste compared to traditional materials like wood or concrete. Its energy-efficient properties also contribute to greener building solutions.

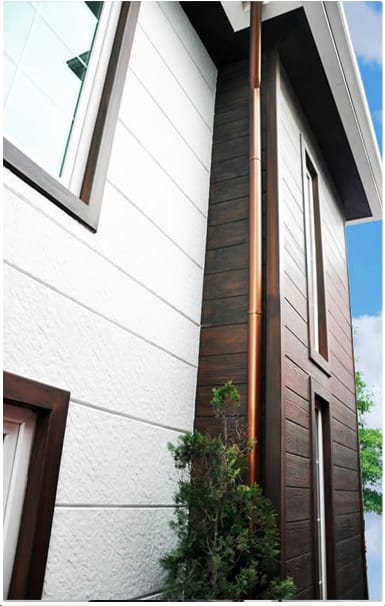

Applications of Light Gauge Steel Construction

Residential Buildings: LGS is commonly used for framing homes, townhouses, and apartment complexes due to its speed of assembly and structural reliability.

Commercial Structures: Office buildings, retail stores, and warehouses benefit from LGS’s strength and efficiency.

Industrial Projects: Factories, workshops, and large-span structures utilize LGS for its durability and load-bearing capacity.

Modular and Prefabricated Units: Light gauge steel is a key material in modular construction, offering flexibility and rapid assembly for container homes, portable offices, and temporary housing.

Why Choose Ever Module for Light Gauge Steel Solutions?

Ever Module specializes in designing and manufacturing high-quality LGS structures tailored to specific project requirements. We integrate advanced technology, precision engineering, and sustainable practices to deliver superior modular and prefabricated solutions. Whether it’s residential, commercial, or industrial applications, our expert team ensures efficiency, durability, and cost-effectiveness in every project.

With Light Gauge Steel, we are building the future—stronger, faster, and greener.